Testing serves an important function in virtually all manufacturing processes. It ensures that the final product’s quality matches the design specifications and is fit for the service environments it will operate in.

There are many ways to classify testing techniques. One of the most popular classifications is destructive and non-destructive testing.

In this article, we shall take a deep dive into what non-destructive testing (NDT) is, some of its popular types and its applications in some common industries.

What Is Non-Destructive Testing?

Non-destructive testing refers to the use of testing techniques that do not alter any of the properties of the tested product. These properties could be its strength, integrity, appearance, corrosion resistance, conductivity, wear resistance, toughness and so on.

Non-destructive testing is also known as non-destructive evaluation, non-destructive analysis, non-destructive examination and non-destructive inspection.

When the product passes an NDT test, it can still be used. There’s no detrimental effect on the specimen because of the test.

This advantage makes non-destructive testing a very useful method for products that are freshly manufactured as well as for those that are already in service.

When the scope of work is simple, using a single NDT process may be sufficient. But in a lot of cases, a combination of techniques and test methods are used for concrete information about the product characteristics.

Difference Between Non-Destructive and Destructive Testing

Non-destructive and destructive testing have some similarities in their objectives but there are significant variations in the core use cases and application methods. In this section, we shall compare and contrast them based on some important factors:

-

Purpose

-

Cost efficiency

-

Time

-

Wastage

-

Safety

-

Reliability of results

Purpose

The purpose of each type of testing is to ensure that we have a safe product. With destructive testing, however, the intention is to find the operational limits for a product through tests such as fatigue and tensile tests.

On the other hand, with NDT, we check whether a manufactured product or one that is already in service is good enough to function satisfactorily in its service environment. We may also use it to assess the extent of wear and tear such as the use of ultrasonic thickness measurement for steel plating of ships.

Cost efficiency

There are two ways in which non-destructive testing is more cost-efficient compared to destructive testing.

Firstly, it does not damage the test specimen. After evaluation through NDT, it will remain just as effective as before and can be put into service right away.

Secondly, NDT can identify potential issues in machinery that is in service, such as a pressure vessel, and recommend replacement before failure occurs, thereby saving breakdown costs that are far costlier than temporary planned downtime for a single part replacement.

Time

When it comes to time, NDT is more effective again. Destructive methods by nature are far more time-consuming processes. This is mainly because destructive testing processes are mostly manual and we can automate fewer components of it. They also require longer preparation and inspection times.

NDT, on the other hand, does not even always need the removal of parts from service thereby saving valuable time. For destructive testing, work must be halted and machines stopped for testing which increases downtime.

Scale Your Manufacturing from Prototyping to Series

- Personal account manager

- Quality assurance

- Payment terms for companies

- On-time delivery by Fractory

Get a quote

Wastage

A test product that undergoes destructive testing becomes unsalvageable. At times, entire machines have to be discarded.

Some examples of destructive methods that create wastage are tensile tests, 3-point bend tests, impact tests and drop tests.

This is not the case with non-destructive testing. In some cases, the destruction may be necessary but in a lot of other cases, non-destructive methods will give us similar or better results.

Safety

Destructive testing is carried out before a product is put into service to determine its operational limits. This may be necessary for some products such as PPE where they must be made to certain standards but destructive testing cannot be used for products in service.

In such cases, NDT methods can help us identify worn-out products and parts so we can replace them. By ensuring that critical equipment is well within desired limits, the number of safety incidents can be brought to a minimum.

Reliability of results

Both destructive and non-destructive testing can give very reliable results. Destructive testing can only test a small number of samples (lot sampling). Non-destructive testing, on the other hand, can test entire batches.

NDT is also a better alternative to find discontinuities and defects in a part.

Non-Destructive Testing Methods

Visual testing

Visual Testing

Visual testing remains the most popular NDT method across all industries. It involves taking a thorough look at the specimen and finding defects that are visible to the naked eye.

It is a quick and feasible method of tracking product quality at every stage of the manufacturing process as well as for those products that are in service.

With visual inspections, we can detect corrosion, cracks, welding defects, deformation, etc. All we need are simple instruments such as rulers, gauges or a camera.

When inspectors are not able to reach hard-to-access places or dangerous environments, drones can often be the solution.

Many industries are in fact using AI and machine learning to improve visual inspection results. For instance, such technology is becoming common in the maintenance of conveyor belts, rollers and pulleys in conveyor systems.

Advantages of visual testing:

Disadvantages of visual testing

-

Only works with surface defects

-

Possible misinterpretation of flaws

-

Cannot detect minute defects without additional optical instruments

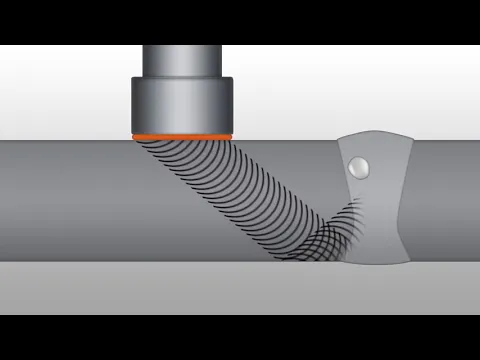

Ultrasonic testing

Ultrasonic Testing

Ultrasonic testing remains the most popular nondestructive testing method after visual testing.

In this method, a high-frequency sound wave generated by a transmitter travels through the object under test. The frequency of this wave is usually between 1 and 10 MHz.

The wave distorts when encountering a change in the density of the material. This change in the transmitted wave is captured by a receiver.

The equipment then measures and analyses the received wave to understand the nature and depth of the defect. The equipment can also calculate the thickness of the specimen by dividing the wave speed in the material by the time taken for travel.

There are many types of ultrasonic testing available each with its nuances and field of application. These are pulse-echo testing, immersion testing, guided wave testing and phased array ultrasonic testing to name a few.

We can identify defects such as cracks, abrasions, thinning, pitting and corrosion using ultrasonic inspection.

Advantages of ultrasonic testing:

-

Quick

-

Clean

-

Reliable

-

Portable

-

Safe and easy to use

-

Highly accurate and sensitive

-

Ability to gauge dense materials

-

Detection of surface and subsurface defects

-

Identifications of minor defects not visible to the naked eye

Disadvantages of ultrasonic testing:

-

Requires training

-

Needs a smooth surface

-

Difficult to use with thin materials

-

Part geometry may create complications

-

Wave propagation speed in tested material must be known for accurate results

-

Couplants are required for smooth wave transfer from the transmitter to the specimen

Liquid penetrant testing

Liquid Penetrant Testing

Liquid penetrant testing is another popular non-destructive testing method used to identify surface-level defects.

In this method, a low-viscosity liquid (penetrant) enters the surface defects such as cracks, fissures and voids. The excess liquid is then wiped off and the specimen is left alone for some time (penetrant dwell time).

The inspector then applies a developer that allows the penetrant to move towards the surface. The specimen is again left alone for a prescribed amount of time (developer dwell time).

Now, the inspector performs the surface inspection. If the dye is visible, it can be inspected with the naked eye. In the case of fluorescent dyes, black light is needed for inspection.

We can detect surface discontinuities such as cracks, porosity, seams, laps and leaks using this method.

Advantages of liquid penetrant tests:

-

Works with many materials. Material properties such as magnetism, conductivity and metallic/non-metallic do not matter

-

Can spot tiny defects such as hairline cracks

-

Suitable for complex part geometries

-

Low cost

-

Can test large areas

-

Portable

-

Easy to use

Disadvantages of liquid penetrant tests:

-

The depth of defects is not known

-

Risk of exposure to toxic fumes

-

Cannot identify subsurface defects

-

Does not work with porous materials

-

Time-consuming, generally needs more than 30 minutes

-

Messy operation, pre- and post-cleaning are necessary

-

Involves handling of chemicals and therefore not it’s not as safe as other methods. Chemical disposal may also become an issue

Radiographic testing

Radiographic Testing

Radiographic testing uses radiation to spot internal defects in parts. X-rays work well with thinner materials whereas gamma rays are better for thicker materials.

The specimen is placed between the radiation source and a recording media. When the radiation falls on the part, the amount of radiation that exits the part in different locations is captured. A physical radiography film or a digital detector is used as the recording media.

The test allows us to obtain the shape and size of internal defects by changing the angle of radiation exposure.

We can use radiographic testing to pinpoint defects such as cracks, thinning, corrosion, voids, insufficient fusion, porosity, excess root penetration and laps.

Advantages of radiographic testing:

-

Can test complex structures

-

Documentation is permanent

-

Works with a range of materials

-

Needs minimum surface preparation

-

Can record surface and subsurface defects

-

Portability is possible for gamma ray testing

-

Less misinterpretation of results compared to other methods

Disadvantages of radiographic testing:

-

More expensive

-

Needs two-sided access to specimen

-

Not as effective for planar and surface defects

-

High voltage and radiation can be harmful to personnel

-

Skilled personnel needed for execution and accurate interpretation of results

Magnetic particle testing

Magnetic Particle Inspection

Magnetic particle testing is also a fairly popular NDT technique because of its fast execution where no surface preparation is needed.

In magnetic particle testing, the part is placed between permanent magnets or electromagnets. The strength of the field is an important factor since a stronger field gives better results.

When the part under inspection is placed into the field, a magnetic current starts flowing through the specimen. If there’s no defect, an uninterrupted magnetic flux field is obtained.

But if it comes across a defect, the magnetic field bends and a part of it leaks out. This leakage is also known as the flux leakage field.

In order to identify the defects via these leakage points, magnetic particles are used. These particles are applied to the test specimen and they are pulled into these leakage points because of the uneven magnetic flux density.

We may either use magnetic particles that can’t be seen with the naked eye or fluorescent ones for better visibility.

The width of the magnetic particle strips is wider than the defect’s width. As a result, it can reveal minute defects with an opening width of up to 0.001 mm and depth of 0.01 mm.

With this technique, we can detect defects such as cracks, pores, laps, inclusions, seams, laminations, shrinks, flakes, welding defects, machining tears and also service-related or fatigue cracks.

Advantages of magnetic particle testing:

-

Easy to use

-

Portable setup

-

High sensitivity

-

Immediate results

-

Usually inexpensive

-

Can work through thin surface coatings

-

Parts with complex geometries are also suitable

-

Visual indication of the shape and size of the defect

-

Can detect surface defects well. Also works for subsurface defects to an extent

Disadvantages of magnetic particle testing:

-

Can only test small areas at a time

-

Does not work with non-magnetic materials

-

Testing may burn the particle if the field is too strong

-

Coatings thicker than 0.1 mm need removal for testing

-

Demagnetisation of test specimens is necessary but may be tricky

-

Can only work for subsurface defects that have a depth of up to 3 mm

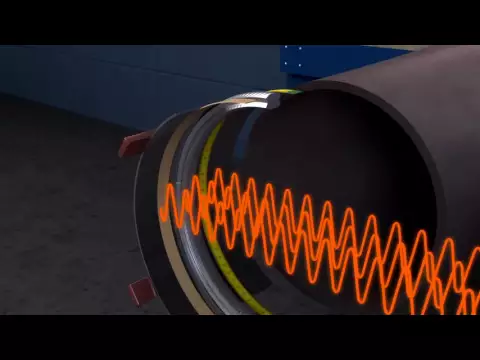

Eddy current

Eddy Current Testing

Like magnetic particle testing, eddy current testing is another electromagnetic testing technique. It works on the principle of electromagnetic induction.

When current passes through any current-carrying conductor (primary conductor), it generates a magnetic field (primary field).

When we place a second conductor (test specimen) in this magnetic field, the primary magnetic field induces an opposing electric current in this conductor.

This current is known as eddy current and it is proportional to the change in the magnetic field as the alternating current in the primary coil rises and falls during every cycle.

The fluctuating eddy current creates its own magnetic field (secondary field) that opposes the primary field and affects the voltage and current flowing through the primary conductor.

As the test specimen’s magnetic permeability and electrical conductivity changes because of the defects, the magnitude of the eddy current changes. These changes can be recorded by using the primary or the secondary coil and analysing them to get more information about the defect.

There are also other testing methods similar to eddy current available. Remote field testing, for example, finds use in detecting defects in steel pipes and tubes. The main difference between the methods lies in the coil-to-coil spacing.

With eddy current testing, we can detect flaws such as cracks, corrosion, laps, lack of fusion, magnetic inclusions, porosity and wear.

Advantages of eddy current testing:

-

Quick

-

Portable

-

Immediate results

-

Minimal part preparation

-

Can be a non-contact process

-

Works with complex part geometries

-

Capable of automation for uniform parts

-

Can spot surface and subsurface defects up to 0.5 mm in size

-

Multipurpose. It can also measure coating and material thickness, identify materials and their heat treatment conditions

Disadvantages of eddy current testing:

-

The penetration depth depends on many factors

-

Cannot detect flaws parallel to the part surface

-

Only works with electrically conductive materials

-

Requires high-skill personnel for accurate interpretation of results

These are some of the most popular NDT techniques used across the industry today. Apart from them, there are many other NDT methods for very specific applications. Some of these are acoustic emission testing, thermal/infrared testing, vibration analysis, leak testing (e.g. mass spectrometer testing), rebound hammer testing, laser testing and so on.

NDT Applications

NDT has a wide range of practical applications. But we can divide all of them into one of the following two categories: quality control and condition monitoring.

We can use nondestructive testing to carry out a quality assessment of the manufactured parts to determine that they meet the desired specifications. We may also use it to assess the condition of parts that are already in service and whether they are safe for further use.

Some common industrial applications of NDT are as follows:

Structural mechanics

NDT can verify the structural mechanics of a wide range of products and structures. It requires minimum intervention and is capable of carrying out routine as well as special inspections without aggravating the issues present in the structure. We may also use it to inspect parts that are not as accessible.

When it comes to civil engineering applications, nondestructive testing can inspect structural foundations, cultural heritage monuments, bridges, buildings, etc.

In mechanical engineering, we use NDT for the inspection of loaded machinery such as shafts, turbomachinery, batteries, etc.

Techniques used in this field include ultrasonic testing, radiography testing, visual testing, acoustic emission testing, terrestrial laser scanning, photogrammetry, tacheometry, infrared thermography, etc.

Welding

NDT techniques can identify the various defects that occur during the welding process. We have enumerated many welding defects in the previous sections that we can reliably test through NDT.

As a quick recap, we can use NDT inspections to identify both external and internal welding defects on both metals and plastics.

External defects include cracks, porosity, undercut, underfill, spatters, overlaps, arc strike and excessive penetration. Internal defects include internal cracks, slag inclusion, tungsten inclusion, internal porosity, internal blowholes, lack of penetration and lack of fusion.

Medical

NDT methods have been revolutionising the medical industry for several years now. They help to accurately diagnose and treatment at the skin as well as the internal level.

Some notable NDT technologies that have become common terms in the medical industry are ultrasound imaging, radiography testing, and echocardiography.

Manufacturers also use NDT methods to test medical implants for fine defects. Such testing prevents subsequent failures when the components are already in use.

Summing it up

Nondestructive testing is quickly becoming the go-to test method for spotting defects in almost every discipline. Today, NDT finds application in sectors such as aerospace, military, medical, nuclear, marine, power generation, manufacturing, etc.

The increasing popularity has prompted further research and the existing processes are becoming better and more capable with every passing year.